|

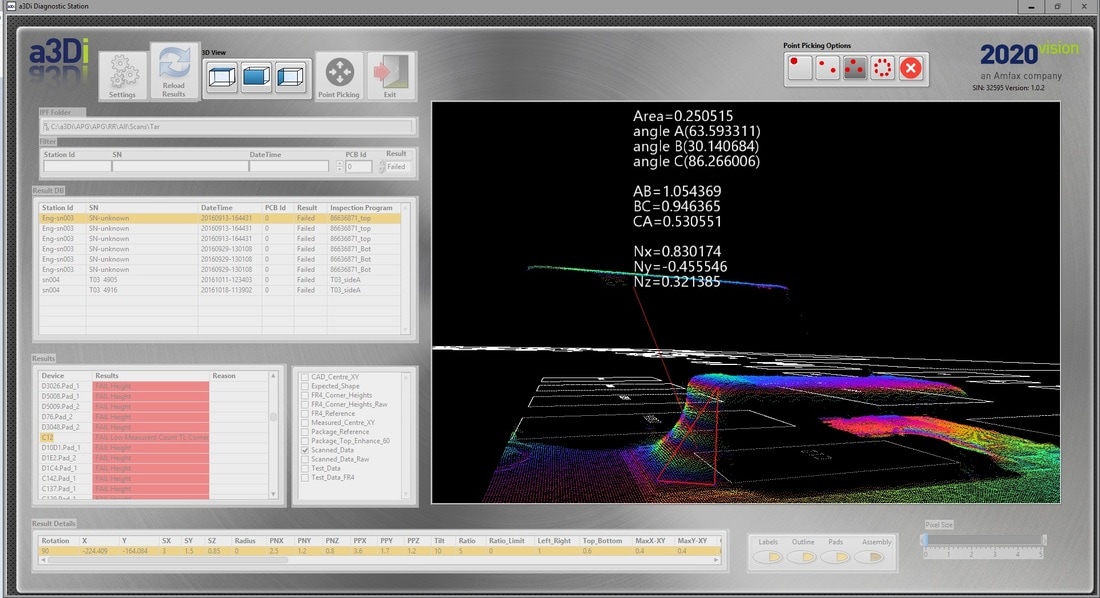

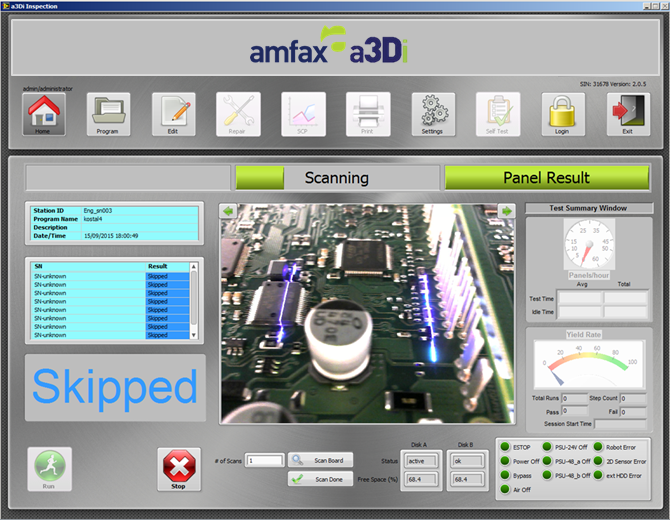

Challenge: To design and develop a revolutionary 3D measurement based Printed Circuit Board Assembly (PCBA) inspection technology to help companies improve the quality of their product. Solution: Combining the benefits of the NI Compact RIO FPGA platform and the user interface qualities of LabVIEW helped Amfax develop the world’s most accurate PCBA inspection system enabling OEM’s and CEM’s to significantly reduce their lifecycle costs. Amfax, are a global Platinum Alliance Partner of 23 years who specialize in designing and manufacturing test engineering solutions for our customers worldwide. Our extensive customer base includes blue chip companies in the aerospace, rail, transport, energy, telecommunications and consumer electronics market sectors. The challenge we have addressed by developing the a3Di PCBA inspection system is that many PCBA manufacturing companies were struggling to solve a problem of accurately and repeatedly inspecting their PCBA to ensure correct component placement and good quality solder joints to improve reliability in use. Historically, humans have been used to visually inspect PCBA’s at the end of the production line. This is prone to poor repeatability and consistency of inspection and as such many companies have switched to Automated Optical Inspection (AOI) systems. These automated systems use cameras in place of the inspectors to capture images of the board and then subjectively compare these images against a reference standard to check if the PCBA has any faults. Any difference between the image and reference standard is flagged by the AOI as a potential failure. The local system operator must then make the final decision as to whether it is a “real” defect or not. There is always a tradeoff in these systems between generating potential failures that an operator reviews, which are known as false fails or relaxing the rules and allowing false passes. Both incur additional operating cost and can potentially affect the products quality. These systems certainly have their place as they provide significant benefits over the human inspection method and have been the system of choice for PCBA inspection for a number of years. The team at Amfax felt there must be a better, more reliable and ultimately more cost effective solution to the inherent problems associated with AOI systems, so set out to design and build the Amfax a3Di. What makes a3Di unique? The Amfax a3Di system takes a completely different approach to address the challenges raised by AOI systems. It users a twin metrology based measurement technology to take millions of measurements with accuracies of under 5 microns to build a compete 3D representation of a PCBA or any other object that can fit inside the a3Di. The system scans a PCBA in a matter of a few seconds and the measurements are tested, one to one, against the original CAD dimensional data to determine whether the board has any problems relating to the component or lead location, orientation and size. Solder joints are also reviewed for shape and volume and can be matched to IPC Class 1,2 and 3 recommendations. Uniquely it measures the complete PCBA and thus can find foreign objects between packages or excessive board warpage on the PCBA that can prevent the PCBA mating with its housing at a future stage. As a3Di is performing real measurement testing, there is no need for an operator as there are no false calls, either the board passes the test or not. That is the advantage of testing against real 3D measurements instead of relying on a comparative methodology such as AOI. The result is zero false calls and no subjective decisions needing to be made by an operator. This means that the users of a3Di save the cost of operators, increase product throughput and more significantly improve their product quality. NI cRIO – The heart of the machine The heart of the a3Di is the control system used to control all aspects of the machines operation. The a3Di was a brand new design for Amfax, so as a Platinum Alliance Partner our first thought was that we must use cRIO. The control system chosen for A3Di is a NI cRIO system using FPGA and the NI 9375D I/O hardware. The performance of this cRIO solution is staggering as it is controlling all of the following I/O and sensors on the a3Di. Machine motors Control switches Optical position sensors Inverters Up and Downstream SMEMA control Light Tower Pneumatics Operator manual controls for width PCB control System side EStop notifications The cRIO has proven to be a completely dependable, reliable and cost effective solution for this high performance, ground breaking application. Using cRIO as the product management system significantly reduced our development time and helped us get the various autonomous state machines of the multiple product control cells run with far tighter timings than the normal 1ms tick of most PLCs. During development, our developers, who are CLD and CLA level engineers, partnered with the technical support teams in the local NI office in the UK who helped the team overcome some of the detailed control issues raised in the systems design. LabVIEW – The obvious choice for user ergonomics A decision was taken early in the a3Di product specification phase to use LabVIEW to not only provide the control code but to control the system from the user interface perspective also. The ability to design product quality operator interfaces and the flexibility of LabVIEW for creating an engaging user interface environment for the operator makes the software front end of a3Di a unique selling point. The impact of using NI components within the a3Di product enables Amfax to offer a world class, unique and well supported solution to those OEMs and CEMs looking to improve their PCBA assembly inspection process and significantly reduce their operational costs.

The a3Di is also revolutionizing the way PCBA manufacturers can now compete for their customers business. By using a3Di, these manufacturers have a unique selling proposition to their own customers. They can pass on savings made by using a3Di and guarantee that the boards being manufactured are being tested by the most accurate system available to do the job. The importance of this exciting technology has not gone unnoticed, with the British Governments innovation department recognising a3Di as a significant step forward in manufacturing. The Amfax a3Di was a finalist at the 2016 Innovate UK awards hosted at the British Houses of Parliament.

4 Comments

23/3/2023 07:50:58 am

With new consumer product upgrade and release cycles becoming tighter, electronics designers need a solution that helps reduce the time involved in each R&D and prototyping cycle.

Reply

17/4/2023 06:33:03 am

It is a nice article about Ni’s compact Rio platform delivering a major impact in the world of PCB assembly inspection. I like how you have researched and presented these exact points so clearly. I agree with all the points that you have stated here, love this blog.

Reply

15/11/2023 12:58:11 pm

Amfax's blog presents a thorough description of the NIS Compact RIO platform, demonstrating its considerable influence on PCB assembly inspection. The essay digs into the product's complexities, giving light on its features and advantages in the field of electronic manufacturing. The text is well-structured, and readers will gain a clear knowledge of how the platform improves Printed Circuit Board PCBA inspection processes.

Reply

Leave a Reply. |

Our recent workWe provide regular updates on the latest projects we have been working on. Check out our archive to view all of our case studies and user solutions. Archives

April 2018

Categories

All

|

RSS Feed

RSS Feed