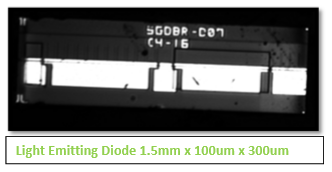

Amfax also integrated an image acquisition system to provide handling with vision. This provided the system with the ability to check the device against an absolute and locate it accurately in X, Y and Theta. We were then able to check for missing devices, devices that were misallocated in their pockets and also for devices that were in the incorrect orientation.

The integration of NI LabVIEW and iMAQ and control of the robot was developed by Amfax to provide a completely interactive environment specifically for handling of opto-electronic devices. The depth of field required to capture the image from the devices is restricted to 150um Temperature controlled test pedestals manufactured from elkanite, a tungsten / copper alloy were used to provide the test bed for the UUT controlled using solid state temperature sensors and Keithley controllers. To allow maintenance of the test head such as replacing Peltier heat pumps the pedestal was mounted on X and Y stages integrated into the assembly. This provided the system with fine adjustment for the UUT location and after replacement the stages could be re-taught to their zero position while not needing to re-teach the robot. The probing assembly was located above the test head and lowered into position via precision stages after the robot had placed the device. The wedge probe design from Pico probe, with kelvin probing incorporated was used for testing the chip. The typical tolerance required to make contact with each mirror was + / - 25um A single mode fibre mounted on an X / Y & Z precession stages was used to align with the wave guide of the device and measure the maximum power once voltage was applied to each mirror using the Pico probe. + / - 5um was required to maintain the sweet spot. The system was housed in a lamina flow filter system mounted on an optically flat, vibration isolated table. The chip trays were fed into the system using a mag handler operated via RS232, the system would request a product to test via an agreed RS232 string sent to the controller, the handler would then take all the steps to place the trays in a position ready for the robot to begin pick and place routine to finally test the devise on the test head

1 Comment

26/4/2018 10:00:31 pm

I didn't know that a probing assembly was located under the test head. This seems like a great way to make sure everything is running properly. Hopefully, companies look into the best testing services.

Reply

Leave a Reply. |

Our recent workWe provide regular updates on the latest projects we have been working on. Check out our archive to view all of our case studies and user solutions. Archives

April 2018

Categories

All

|

RSS Feed

RSS Feed